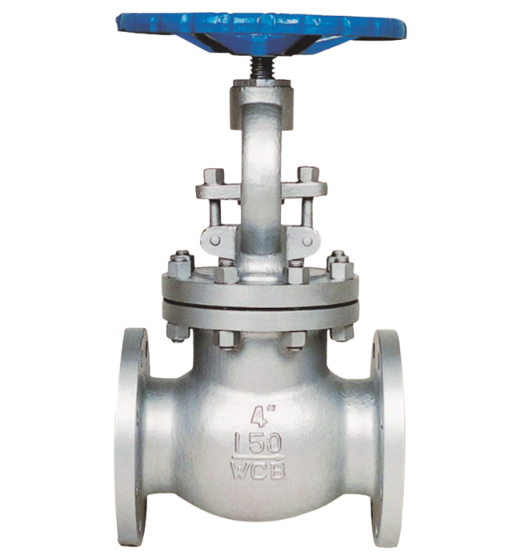

Gate Valve

Design Features

Trims : 13% Cr stem-wedge in CA 15 or 13% Cr faced, and Co-Cr alloy faced seat API trim 8 suitable for applications up to 850° F (454° C).

Flexible wedge with centre stem-wedge contact in solid CA15 (13% Cr) or hand faced with 13% Cr, SS 316 Monel or Co-Cr alloy. Wedge is ground and lapped to a mirror finish and tightly guided to prevent dragging and seat damage.

Non-rotating stem with precision acme threads and burnished finish. Double acme for faster operation.

Body and bonnet joint accurately machined. Spiral wound Gasket with different grade of material which can withstand high temperatures and pressures, preventing leaks throughout their intended life span.

Body and bonnet casting are precision machined. One-piece bonnet up to NPS 12 (DN 300) for better alignment and fewer parts.

Flanges : Finish 125-250 AARH for all valves.

¢ ASME Classes 150-300 : 2mm raised face

¢ ASME Classes 600-up : 7mm raised face

RTJ available on client requirement.

| Part | Material | ||

|---|---|---|---|

| Body | WCB | CF8 | CF8M |

| Bonnet | WCB | CF8 | CF8M |

| Stem | SS 410 | SS 304 | SS 316 |

| Wedge | CA15 or 13% Cr faced | CF8 | CF8M |

| Seat Ring | 13% Cr. Or STL. | Co-Cr Alloy Faced | Co-Cr Alloy Faced |

| Gland Flanged | Carbon Steel | Stainless Steel | Stainless Steel |

| Gland Bushing | Carbon Steel | Stainless Steel | Stainless Steel |

| Packing Ring | Die Formed Flexible Graphite Ring (Renewable) | ||

| Gland Stud | Gr.B7 | Gr.B8 | B8M |

| Gland Stud | Gr.2H | Gr.8 | Gr.8M |

| Body/Bonnet Nut | Gr.2H | Gr.8 | Gr.8M |

| Body/Bonnet Stud | Gr.BH | Gr.B8 | B8M |

| Back Seat | SS 410 | SS 304 | ss 316 |

| Gasket | Class 150 : Corrugated Steel / Graphite Class 300 – 1500 : Spiral Wound Stainless Steel/ Graphite |

||

| Key | Carbon Steel | ||

| Yoke Bushing | Carbon Steel | Stainless Steel | Stainless Steel |

| Handwheel Nut | Malleable Iron Or Steel | ||

| Handwheel | Malleable Iron Or Ductile Iron | ||

| Name Plate | Stainless Steel | ||

| Stem Nut | A 439 Austenitic Ductile Iron Gr. D-2c | ||

| Item | Applicable STD |

|---|---|

| Design Standard | API 600 / ISO 10434 |

| Face-to-Face Dimensions | ASME B16.10 |

| Testing Standard | API 598 / BS 6755 |

| Flange Design | ASME B16.5 / DIN |

| Butt Welding Design | ASME B16.5 |

| Materials | ASME B16.34 |

| Pressure-Temperature Rating | ASME B16.34 |

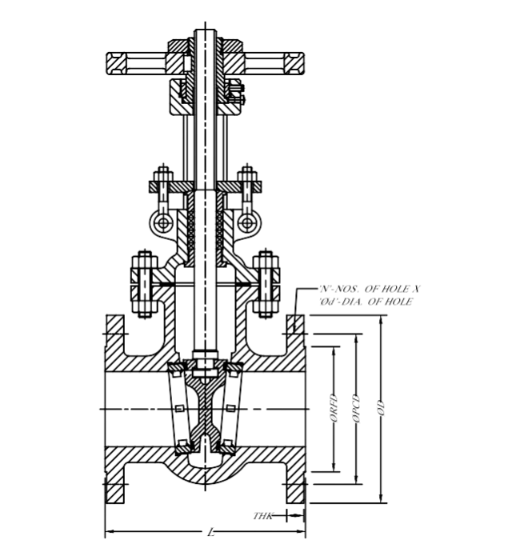

Gate Valve Dimensions

| Size | 2” | 2 ½” | 3” | 4” | 5” | 6” | 8” | 10” | 12” | 14” | 16” | 18” | 20” | 24” |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 178.0 | 191.0 | 203.0 | 229.0 | 254.0 | 267.0 | 292.0 | 330.0 | 356.0 | 381.0 | 406.0 | 432.0 | 457.0 | 508.0 |

| ØD | 150.0 | 180.0 | 190.0 | 230.0 | 255.0 | 280.0 | 345.0 | 405.0 | 485.0 | 535.0 | 595.0 | 635.0 | 700.0 | 815.0 |

| THK | 17.5 | 20.7 | 22.3 | 22.3 | 22.3 | 23.9 | 27.0 | 28.6 | 30.2 | 33.4 | 35.0 | 38.1 | 41.3 | 46.1 |

| RFD | 92.0 | 105.0 | 127.0 | 157.0 | 186.0 | 216.0 | 270.0 | 324.0 | 381.0 | 413.0 | 470.0 | 533.0 | 584.0 | 692.0 |

| PCD | 120.7 | 139.7 | 152.4 | 190.5 | 215.9 | 241.3 | 298.5 | 362.0 | 431.8 | 476.3 | 539.8 | 577.9 | 635.0 | 749.3 |

| Ød | 19.05 | 19.05 | 19.05 | 19.05 | 22.23 | 22.23 | 22.23 | 25.40 | 25.40 | 28.58 | 28.58 | 31.75 | 31.75 | 34.93 |

| N | 4 | 4 | 4 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 16 | 16 | 20 | 20 |

| Size | 2” | 2 ½” | 3” | 4” | 6” | 8” | 10” | 12” | 14” | 16” | 18” | 20” | 24” |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 216.0 | 241.0 | 282.0 | 305.0 | 403.0 | 419.0 | 457.0 | 501.0 | 762.0 | 838.0 | 914.0 | 990.0 | 1143.0 |

| ØD | 165.0 | 190.0 | 210.0 | 255.0 | 320.0 | 380.0 | 445.0 | 520.0 | 585.0 | 650.0 | 710.0 | 775.0 | 915.0 |

| THK | 20.7 | 23.9 | 27.0 | 30.2 | 35.0 | 39.7 | 46.1 | 49.3 | 52.4 | 55.6 | 58.8 | 62.0 | 68.3 |

| RFD | 92.0 | 105.0 | 127.0 | 157.0 | 216.0 | 270.0 | 324.0 | 381.0 | 413.0 | 470.0 | 533.0 | 584.0 | 692.0 |

| PCD | 127.0 | 149.2 | 168.3 | 200.0 | 269.9 | 330.2 | 387.4 | 450.8 | 514.4 | 571.5 | 628.6 | 685.8 | 812.8 |

| Ød | 19.05 | 22.22 | 22.22 | 22.22 | 22.22 | 25.40 | 28.57 | 31.75 | 31.75 | 34.93 | 34.93 | 34.93 | 41.28 |

| N | 8 | 8 | 8 | 8 | 12 | 12 | 16 | 16 | 20 | 20 | 24 | 24 | 24 |

| Size | 2” | 2 ½” | 3” | 4” | 6” | 8” | 10” | 12” | 14” | 16” | 18” | 20” | 24” |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 292.0 | 330.0 | 356.0 | 432.0 | 559.0 | 660.0 | 787.0 | 838.0 | 889.0 | 990.0 | 1092.0 | 1194.0 | 1397.0 |

| ØD | 165.0 | 190.0 | 210.0 | 275.0 | 355.0 | 420.0 | 510.0 | 560.0 | 605.0 | 685.0 | 745.0 | 815.0 | 940.0 |

| THK | 25.4 | 28.6 | 31.8 | 38.1 | 47.7 | 55.6 | 63.5 | 66.7 | 69.9 | 76.2 | 82.6 | 88.9 | 101.6 |

| RFD | 92.0 | 105.0 | 127.0 | 157.0 | 216.0 | 270.0 | 324.0 | 381.0 | 413.0 | 470.0 | 533.0 | 584.0 | 692.0 |

| PCD | 127.0 | 149.2 | 168.3 | 215.9 | 292.1 | 349.2 | 431.8 | 489.0 | 527.0 | 603.2 | 654.0 | 723.9 | 838.2 |

| Ød | 19.05 | 22.22 | 22.22 | 25.40 | 28.57 | 31.75 | 34.92 | 34.92 | 38.10 | 41.28 | 44.45 | 44.45 | 50.80 |

| N | 8 | 8 | 8 | 8 | 12 | 12 | 16 | 20 | 20 | 20 | 20 | 24 | 24 |

Other Products